SKF Services

Associated’s Project SKF Service

At Associated, we understand that effective lubrication management is crucial for maintaining equipment performance, reducing downtime, and optimizing costs. Partnering with Shell Lubricant Services, we offer comprehensive solutions to ensure your machinery runs smoothly and efficiently. Discover our services designed to enhance your operations and extend the life of your equipment.

Spindle Refurbishment & Bearing Re-manufacturing

Associated, in collaboration with SKF Solution Factory, offers spindle refurbishment and bearing re-manufacturing services designed to restore your equipment to peak performance. With over 1,000 repairs annually across our centers in Pune, Bangalore, Jamshedpur, and Manesar, we deliver unmatched value and dependability.

Advantages of Spindle Service:

- Maximize spindle performance to improve productivity

- Decrease downtime and reduce maintenance costs

- Improve spindle reliability with the industry’s best warranty

- Emergency services available

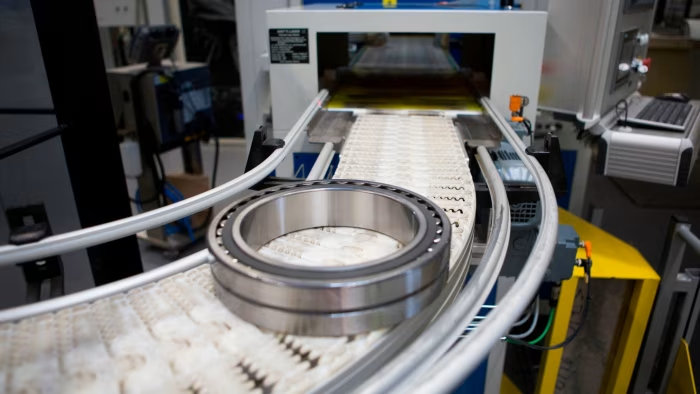

Industrial Bearing Re-manufacturing

Industrial bearings often suffer from wear, rust, and other damages, shortening their service life. Associated’s controlled re-manufacturing process restores bearings to their original condition, prolonging their lifespan and reducing costs. This process is also more environmentally friendly compared to manufacturing new bearings.

Suitable for Large Bearings:

- Spherical Roller Bearings

- Single- and Multi-Row Tapered Roller Bearings

- Cylindrical Roller Bearings

- Deep Groove Ball Bearings

- CARB Toroidal Roller Bearings

- Spherical Roller Thrust Bearings

Rotating Equipment Performance (REP)

Rotating equipment is the backbone of many industrial processes. With SKF’s expertise, Associated offers solutions to enhance the performance of your rotating equipment, driving down costs and increasing output.

Key Benefits:

- Cost Reduction: Lower operational, maintenance, and energy costs.

- Improved Output: Increase availability, performance rate, and quality.

- Ensure Compliance: Meet health, safety, and environmental standards.

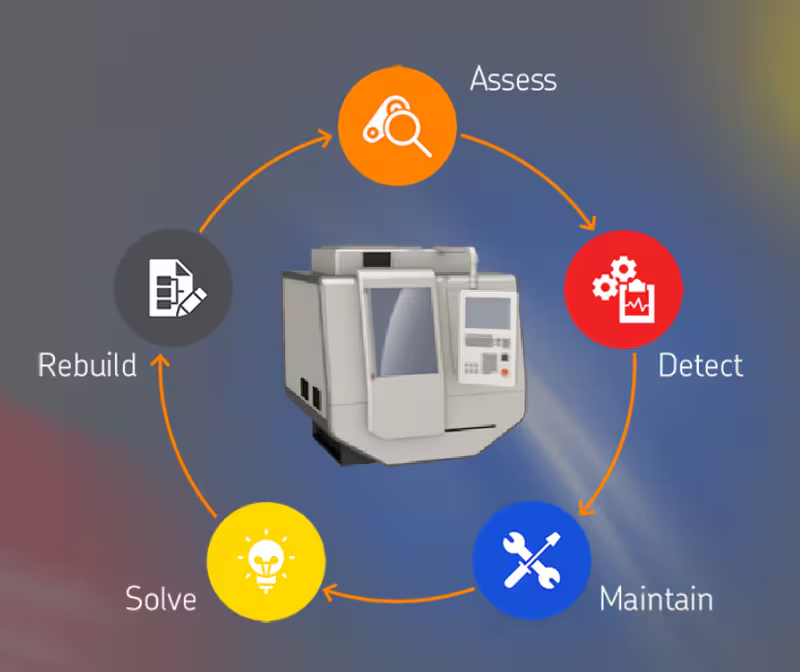

SKF Certified Maintenance Partner

As an SKF Certified Maintenance Partner, Associated provides advanced machine reliability services to help you monitor, predict, and optimize machine performance. Our services include a range of diagnostic and maintenance activities designed to keep your equipment running smoothly.

Maintenance Services:

- Vibration Analysis, Lubrication Analysis, and Visual Inspection

- Shaft Alignment and Dynamic Balancing

- Root Cause Failure Analysis (RCFA)

- Machine Inspection Service and Repair