Power transmission

Belts

Improve plant efficiency with accurate belt selection

Plant efficiency is a key performance indicator, and one that most manufacturers want to improve.

In power transmission, our Plant Belt Drive Mapping service has helped many customers to achieve this. After assessing all belt drives within a facility, our technical experts recommend how best to raise efficiency and extend operating lifetimes.

Choosing higher quality belts can reduce the total cost of ownership of machinery over the long term. We offer a variety of belts, from standard V-belts to high-performance ‘Extra Power’ belts that can transmit up to 40% more power than standard products. However, identifying exactly which product you need from such a broad selection can be simplified by using our clear selection tools. To make specification quick and simple, click through to SKF’s online catalogue for a clear description of each product type, before defining specific details. Here, you can find the full range of parts that you need.

Pulleys

Match your pulleys to your belts for extended service life

Cost efficiency is critical in engineering, including power transmission projects. Designers need high quality components in order to maintain performance and contain operating costs.

The superior quality of our pulleys can significantly extend belt life, which helps to reduce the total cost of ownership of your machinery. We offer a wide variety of pulleys, in all types of profile. These include wedge belt, V-belt and narrow wedge belt pulleys, plus classical and metric timing pulleys and more.

We ease the task of choosing the best pulley for an application: a heavy-duty timing belt, for instance, will require a robust, high performance pulley.

Chains

Reduce maintenance costs with robust quality chain

Mean-time-between-failures (MTBF) is an important measure of reliability, and is critical in power transmission systems. Robust chain drives extend mean-time-between-failures, which reduces maintenance costs.

Some chain systems are of inferior quality, having low wear resistance and little ability to withstand harsh conditions such as temperature variation and shock loading.

Our wide variety of chains include many high-performance variants, and are often specified when other products fail. One of our customers – a foundry in India – found that locally made chains wore out very quickly. Using our roller chains, they cut downtime and maintenance costs by 40%.

All our chains undergo strict quality control from monitoring the raw material used in individual components, to testing the finished products. Chain drive calculators, power rating tables and expertise from our engineers help you to specify a chain correctly.

Sprockets

Find the perfect sprocket for your application

Selecting a power transmission component can be challenging, especially when it is a fundamental part like a sprocket.

Products must be available in many sizes, to fit a variety of design envelopes – and avoid the need for customised parts. With our comprehensive range, you will easily find the correct sprocket size for your application.

All our sprockets are made from high-quality steels and can be further adapted for high performance with coatings such as black oxide or zinc plating. Sprockets are available in a variety of configurations, which must be matched accurately to a machine’s design.

Couplings

Power transmission couplings that meet your specific requirements

Machine designers are under pressure to raise the performance of power transmission systems, in the face of diminishing time and resources.

A diversity of coupling systems, including customised products, helps these systems work effectively and efficiently. Factors such as size and torque requirements determine the most appropriate coupling to use.

We offer all the main types, including grid, gear, flex and jaw couplings. In addition we supply OK couplings, which use oil injection for mounting and dismounting, and flexible shaft couplings.

Flexible shaft couplings compensate for four types of shaft misalignment: angular, offset, a combination of the two, and axial movement. Grid couplings are aimed at high output, high torque gear applications, while gear couplings are heavy duty products with large bore capacities.

Most products are made from cast iron, though some (such as chain couplings) use carbon steel. Surface treatment techniques, including phosphate coating, help to protect against corrosion.

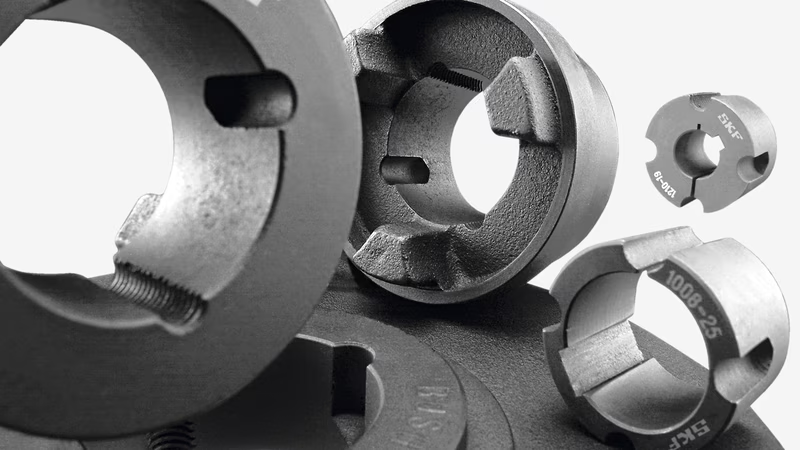

Bushings and hubs

Simplify installations with easy-to-fit, high-quality bushings and hubs

Bushings and hubs are available in many variants, offering specific benefits in power transmission applications ranging from automotive to paper making.

Our products are made of high-quality steel. Most are phosphate-coated or blackened to improve corrosion resistance. We offer taper, QD and keyless bushings, as well as weld-on and bolt-on hubs. In addition, our SH bushings withstand heavy loads (for both torque and axial forces), and extremes of temperature.

All bushings are easily installed and removed using basic tools, so there is minimal downtime each time they are fitted. A good example is our FX keyless bushings, which have a 360-degree interference fit. This enables components to be easily positioned and mounted without the need for a keyway.

This wide availability of sizes and types means that no customisation is needed, and a matching product is available off-the-shelf at short notice.

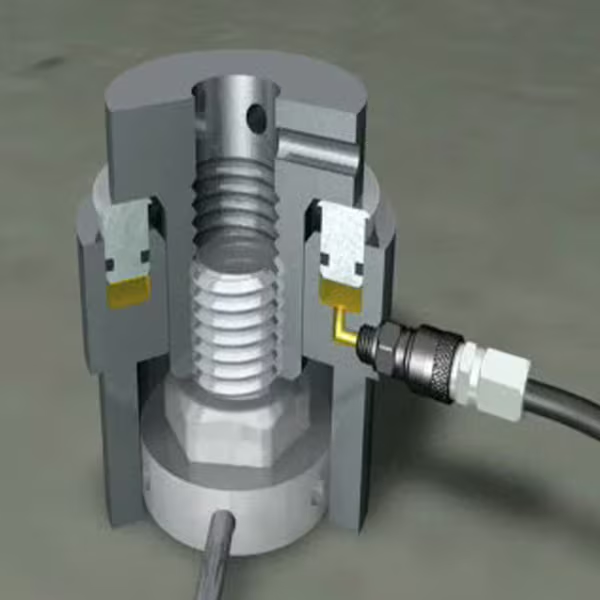

Bolts and tightening systems

In maintenance, time is money. However, if basic jobs such as bolt tightening are not carried out correctly, this can lead to failure in bolted assemblies. This can be avoided with our hydraulic tensioning systems, which apply precise tightening forces to bolts. They apply high force without torsional stress or friction, but with high precision and repeatability. Hydraulic tensioners are available for everything from standard bolts to special applications.

Tightening systems are widely used, in areas as diverse as steam turbines and ship propellers. We have special products for both applications. In steam turbines, our Cold Tight systems reduce the downtime each time a steam turbine is opened or closed. It avoids the need for long cool-down periods. Similarly, applying our oil-injection method to hydraulic rings and propeller nuts simplifies and speeds up the mounting and dismounting of propellers from shafts.

We’ve also developed our Supergrip range of bolts, which are easy to install and remove. They are used to connect rotating flange couplings.

To carry out a product search, click the ‘Online Catalogue’ button, and select a product from the drop-down menu.